Produtos

DUPLA CABEÇA – IPC

Características do equipamento

Um mandril giratório rápido de 90 graus é instalado para mover o conjunto de baterias com ponto de soldagem de direção inconsistente.

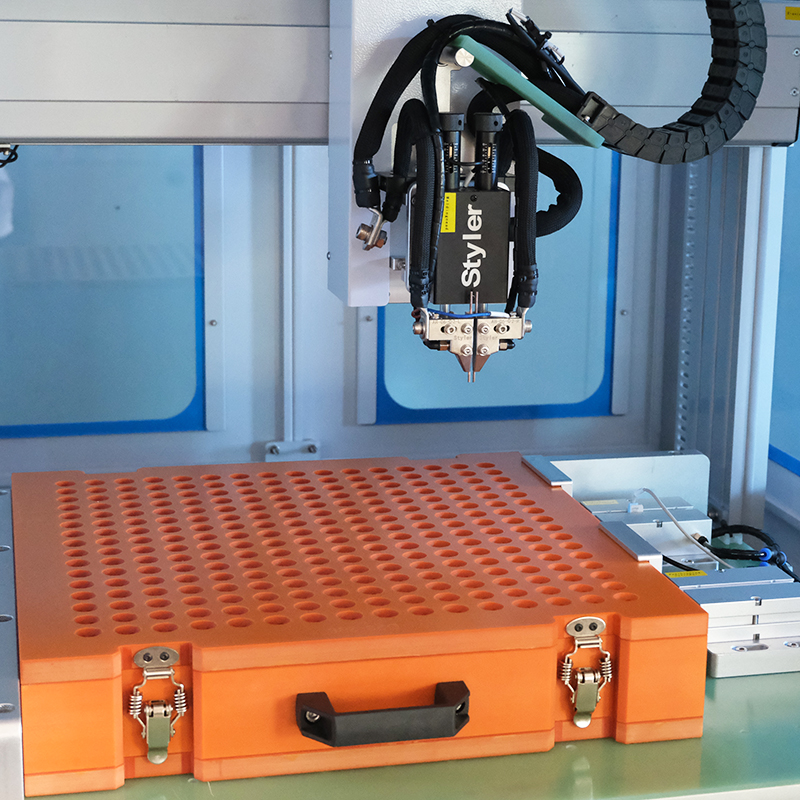

Os controles de operação, mapas CAD, cálculos de múltiplas matrizes, porta de inserção de driver portátil, controle de área parcial e recursos de soldagem virtual de ponto de interrupção tornam a máquina mais fácil de usar.

O IPC funciona junto com a placa de controle de movimento para melhorar o movimento da agulha e o desempenho da soldagem.

O scanner conectado pode ler o número da bateria e recuperar o parâmetro de soldagem, ao mesmo tempo em que salva os dados localmente ou pela nuvem.

Compatível com sistema EMS.

Acessórios opcionais

Grade de segurança (luz infravermelha detecta que, quando a máquina está em funcionamento, se houver algo ou uma mão entrando, ela irá parar ou emitir um alarme para proteção)

Controle de acesso (a máquina pode ser configurada para desligar quando a porta for aberta durante a operação para proteção)

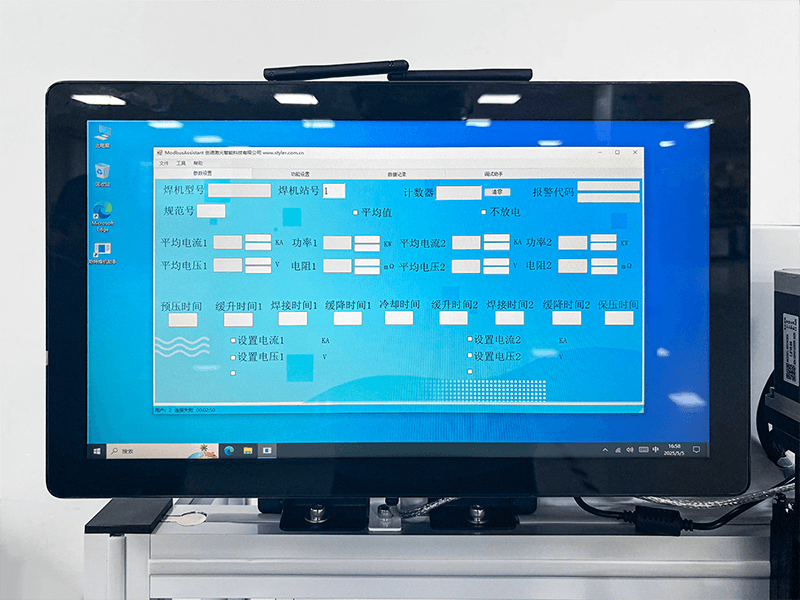

monitoramento em tempo real dos pontos de soldagem e capacidade de enviar os dados de soldagem salvos da máquina via RS485

Fixação (dispositivo para fixação de baterias, personalizável)

Pistola de digitalização: digitalize o código para selecionar o programa de soldagem e soldar automaticamente

Por que nos escolher

A Styler conta com uma equipe profissional de engenharia e serviço técnico, fornece linha de produção automática de baterias de lítio PACK, orientação técnica de montagem de baterias de lítio e treinamento técnico.

Podemos fornecer uma linha completa de equipamentos para produção de baterias.

Podemos fornecer o preço mais competitivo diretamente da fábrica.

Podemos fornecer o serviço pós-venda mais profissional 24 horas por dia, 7 dias por semana.

Conhecimento científico popular

Esta máquina de solda pneumática a ponto é usada principalmente para soldagem de cilindros 18650, ela pode soldar espessuras de abas de níquel de 0,02-0,2 mm com bom efeito de soldagem.

O modelo pneumático tem menor volume e peso, facilitando o transporte internacional.

Agulha de ponta única pode ser usada para solda de aba de níquel com caixa de aço inoxidável.

1. Controle de microcomputador, ajuste de corrente CNC.

2. Alto poder de soldagem de precisão.

3. Visor digital do tubo, controle do teclado, armazenamento flash dos parâmetros de soldagem.

4. Soldagem por pulso duplo, torna a soldagem mais firme.

5. Pequenas faíscas de soldagem, aparência uniforme da junta de solda, a superfície está limpa.

6. Os tempos de soldagem podem ser definidos.

7. É possível definir o tempo de pré-carregamento, o tempo de espera, o tempo de descanso e a velocidade de soldagem pode ser ajustada.

8. Grande potência, estável e confiável.

9. Pressão de agulha dupla ajustável separadamente, adequada para diferentes espessuras de tira de níquel.

R: Envie-nos seu pedido de compra por e-mail ou ligue para o nosso departamento de vendas, ou podemos emitir uma fatura pró-forma conforme sua solicitação. Precisamos das seguintes informações do seu pedido antes de enviar suas informações pessoais.

1) Informações sobre o produto - quantidade, especificação (tamanho, material, tecnologia, se necessário, e requisitos de embalagem, etc.

2) Prazo de entrega necessário.

3) Informações de envio: nome da empresa, endereço, número de telefone, porto marítimo de destino.

4) Detalhes de contato do despachante, se houver algum na China.

Sempre uma amostra de pré-produção antes da produção em massa; Sempre inspeção final antes do envio.

Linha de automação de montagem de bateria de lítio, máquina de solda a ponto de bateria, máquina de classificação de bateria, sistema de teste abrangente de bateria, gabinete de envelhecimento de bateria.

Contamos com uma forte equipe técnica de P&D e atuamos na indústria de montagem e fabricação de baterias de lítio há muitos anos, com vasta experiência. A empresa conta atualmente com uma variedade de especificações e modelos de máquinas e equipamentos, em diversas séries.

R: Nosso sistema de P&D é baseado em uma visão de desenvolvimento integrado. Ao adquirir a máquina, basta conectá-la à energia elétrica e ela estará pronta para uso, pois o software em inglês foi instalado nesta máquina. Basta aprender a usar o software e o manual do usuário completo em inglês será enviado junto com a máquina.